Scientists unlock secret to thick, stable beer foams

For many beer lovers, a nice thick head of foam is one of life’s pure pleasures, and the longer that foam lasts, the better the beer-drinking experience. A team of Swiss researchers spent seven years studying why some beer foams last longer than others and found that the degree of fermentation—i.e., whether a given beer has been singly, doubly, or triply fermented—is crucial, according to a new paper published in the journal Physics of Fluids.

As previously reported, foams are ubiquitous in everyday life, found in foods (whipped cream), beverages (beer, cappuccino), shaving cream and hair-styling mousse, packing peanuts, building insulation, flame-retardant materials, and so forth. All foams are the result of air being beaten into a liquid formula that contains some kind of surfactant (active surface agent), usually fats or proteins in edible foams, or chemical additives in non-edible products. That surfactant strengthens the liquid film walls of the bubbles to keep them from collapsing.

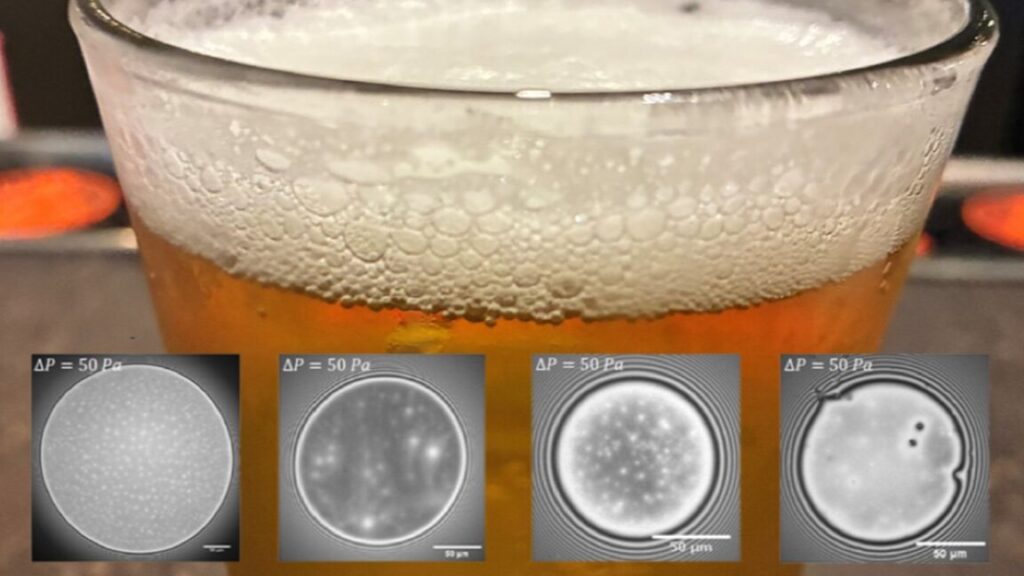

Individual bubbles typically form a sphere because that’s the shape with the minimum surface area for any volume and hence is the most energy-efficient. One reason for the minimizing principle when it comes to a bubble’s shape is that many bubbles can then tightly pack together to form a foam. But bubbles “coarsen” over time, the result of gravity pulling down on the liquid and thinning out the walls. Eventually, they start to look more like soccer balls (polyhedrons). In a coarsening foam, smaller bubbles are gradually absorbed by larger ones. There is less and less liquid to separate the individual bubbles, so they press together to fill the space.

This “jamming” is why foams are typically far more rigid than their gas (95 percent) and liquid (5 percent) components. The more tightly the bubbles jam together, the less they can move around and the greater the pressure inside them becomes, giving them properties of a solid.

Various factors can affect foam stability. For instance, in 2019, Japanese researchers investigated a phenomenon known as “collective bubble collapse,” or CBC, in which breaking one bubble at the edge of a foam results in a cascading effect as the breakage spreads to other bubbles in the foam. They identified two distinct mechanisms for the resulting CBCs: a so-called “propagating mode,” in which a broken bubble is absorbed into the liquid film, and a “penetrating mode,” in which the breakage of a bubble causes droplets to shoot off and hit other bubbles, causing them to break in turn.

Scientists unlock secret to thick, stable beer foams Read More »