Custom machine kept man alive without lungs for 48 hours

Infections had turned his lungs to soup and had to be cleared before transplant.

Humans can’t live without lungs. And yet for 48 hours, in a surgical suite at Northwestern University, a 33-year-old man lived with an empty cavity in his chest where his lungs used to be. He was kept alive by a custom-engineered artificial device that represented a desperate last-ditch effort by his doctors. The custom hardware solved a physiological puzzle that has made bilateral pneumonectomy, the removal of both lungs, extremely risky before now.

The artificial lung system was built by the team of Ankit Bharat, a surgeon and researcher at Northwestern. It successfully kept a critically ill patient alive long enough to enable a double lung transplant, temporarily replacing his entire pulmonary system with a synthetic surrogate. The system creates a blueprint for saving people previously considered beyond hope by transplant teams.

Melting lungs

The patient, a once-healthy 33-year-old, arrived at the hospital with Influenza B complicated by a secondary, severe infection of Pseudomonas aeruginosa, a bacterium that in this case proved resistant even to carbapenems—our antibiotics of last resort. This combination of infections triggered acute respiratory distress syndrome (ARDS), a condition where the lungs become so inflamed and fluid-filled that oxygen can no longer reach the blood.

In this case, the infections were necrotizing—the cells in the lungs were dying, turning his lung tissue into a liquid. The surgeons faced a seemingly impossible choice. The patient needed a transplant to survive, but he was in refractory septic shock. His kidneys were shutting down, and his heart was failing to the point where it completely stopped shortly after hospital admission. The doctors had to bring him back with CPR.

He was too sick for a transplant, yet the very organs that needed replacing were the source of the infection fueling his decline. “When the infection is so severe that the lungs are melting, they’re irrecoverably damaged,” Bharat explained. “That’s when patients die.”

But this patient did not die.

The empty chest problem

To save him, Bharat’s team had to remove the infected lungs, a procedure called a bilateral pneumonectomy, to remove the source of the sepsis. We have machines that can oxygenate the blood. But removing both lungs creates a lethal mechanical problem for the heart.

The human heart is two pumps in one. The right side, called the pulmonary circuit, pumps oxygen-poor blood returning from the body into the lungs, which remove its carbon dioxide and load it with a fresh supply of oxygen. The left side, known as the systemic circuit, receives freshly oxygenated blood and pumps it to the rest of the body. The pulmonary vascular bed, all these miles of tiny vessels inside the lungs, facilitates this gas exchange. But it also acts as a capacitor, absorbing the pressure and volume of the blood ejected by the right ventricle.

If you remove the lungs and simply shut the pulmonary arteries, the right ventricle has nowhere to pump—it would experience an immediate, massive pressure spike, distend like a balloon, and fail within minutes. At the same time, the left side of the heart would have no blood returning to it, leading to a total collapse of blood pressure and systemic circulation.

This is the reason why most double-lung transplants are performed sequentially: The surgeons replace one lung, get it up and running, and then move on to the second. But desperate times require desperate measures.

The last line of defense

In rare cases where both lungs must be removed at once, a patient can still be supported by the Extracorporeal Membrane Oxygenation (ECMO), a mechanical lung that takes blood out of the body, removes the carbon dioxide, adds oxygen, and pumps it back in. The problem is that while ECMO can support a person for up to over a year when their lungs are still in their body, the risks of using it skyrocket when the lungs are removed.

The empty chest cavity creates a void where blood and fluids can pool, leading to huge internal bleeding. The heart, which relies on the physical presence and pressure of the lungs to maintain its proper anatomical position, can flop around or collapse. Finally, circulating blood through complex machinery significantly increases the risk of stroke or clotting.

Because of all these risks, surgeons always treat removing both lungs as the last line of defense, one they can only rely on for a short time—the shorter the better. Bharat and his colleagues, though, had to keep their patient this way until the sepsis had been dealt with.

It wasn’t enough for the team to keep the patient alive without lungs in his body until the transplant arrived. In this lungless state, somehow, they had to improve his health.

Synthetic lungs

To make this happen, Bharat’s team engineered a device they called the “flow-adaptive extracorporeal total artificial lung system” (TAL), a complex circuit designed to mimic the physics of the missing organs. At its core was a pump and an oxygenator borrowed from the standard ECMO setup, but it also used four new components to replace biological functions.

The first was a dual-lumen cannula, essentially a single tube with two separate channels inside. Inserted through the internal jugular vein, this tube acted as the primary drain. It allowed the team to pull deoxygenated blood directly from the right side of the heart, unloading the right ventricle to prevent it from distending.

The second component was something the researchers called a flow-adaptive shunt, which connected the right pulmonary artery back to the right atrium. When the right ventricle pumped out more blood than the external pump could handle, the excess blood would safely recirculate back into the atrium through this low-resistance path, protecting the heart and the surgical staples from pressure spikes. During the 48 hours the patient was supported by the TAL, this shunt self-regulated its flow to anywhere between 1.1 and 6.3 liters per minute, based on the patient’s needs.

To ensure the left side of the heart stayed full and active, the team used a device called dual left atrial return. It comprised two 10 mm grafts that returned oxygenated blood from the ECMO artificial lung directly into the left atrium. This, the team said in a paper that describes the hardware, maintained what’s called Starling physiology: the principle that the heart pumps better when it is properly filled. It also prevented blood from stagnating and forming clots inside the heart chambers.

Finally, to prevent the heart from physically shifting and damaging vital vessels in the empty chest cavity, the surgeons used bovine pericardium to reconstruct the heart’s protective sac and filled the empty space with tissue expanders and surgical sponges.

Lungless recovery

The results of hooking the patient up to TAL were immediate.

Within hours of the surgery, the patient’s septic shock began to resolve. His lactate levels, a key marker of tissue oxygen starvation, dropped from a dangerous 8.2 mmol/L to a normal level of less than 1.0 mmol/L within 24 hours. The medications used to keep his blood pressure up were discontinued after just 12 hours.

For two days, the patient lived as a human being with no lungs, stabilized by a machine that breathed and buffered his circulation with surgical precision. When donor lungs became available 48 hours later, the patient’s body was no longer suffering from sepsis.

He was ready for the transplant, which the team successfully performed. And after putting in the new lungs, they focused on the lungs they had removed.

When lungs die

Conventionally, patients with ARDS do not get transplants because doctors hope that with the right treatment and support, the diseased lungs will eventually heal. But the examination of the infected lungs removed from Bharat’s patient told a different story and helped define the clinical point of no return, when a lung is truly dead.

Based on the spatial transcriptomics, a set of techniques that let scientists see which genes are active at different sites in the tissue, the team built a high-resolution molecular map of the removed lungs. What they found was a landscape of total devastation.

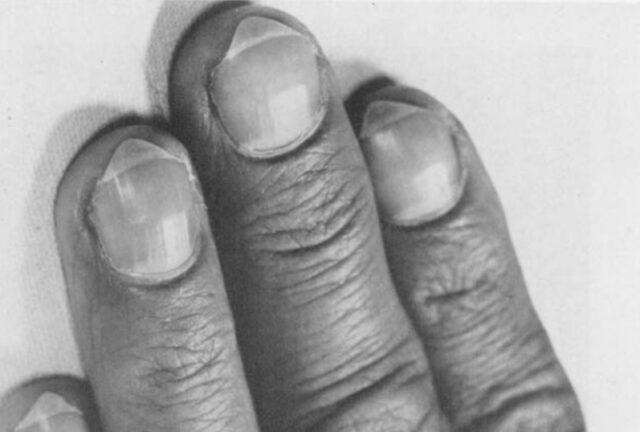

The lungs were filled with aberrant basaloid cells—a signature of failed regeneration. The stem cells required to rebuild the lungs were almost entirely gone. The architecture was uniformly destroyed and replaced by cells that were laying down scar tissue.

“People think if you get severe ARDS, you keep supporting them and ultimately the lungs will get better,” Bharat says. The data collected by his team suggested no amount of waiting or life support would have brought this patient’s lungs back to life. “In my practice, young patients die almost every week because no one realized that transplantation was an option,” Bharat added.

Tough choices

In many hospitals, patients with severe, acute lung infections are often allowed to die because they are considered too unstable for surgery. While Bharat’s study offers some hope that this situation might improve in the future, the team admits that their approach currently requires immense expertise and access to a highly specialized medical center with donor lungs. Making expertise and resources more accessible will take some time.

And that’s not the only thing we have to wait for. Bharat and his colleagues note in their paper that one key challenge in ARDS is determining whether the injury is reversible. His study offers some initial insights into diagnosing irreversible damage, but the researchers note that their conclusions were based on a single case. The features of lungs that are beyond repair may differ across various pathogens, stages of disease, or the way individual patient’s body responds to the disease.

For Bharat’s patient, though, all possible stars aligned. The paper says that two years after the procedure, he has returned to a normal, independent life with excellent lung function.

Med, 2026. DOI: 10.1016/j.medj.2025.100985

Custom machine kept man alive without lungs for 48 hours Read More »