Hands-off charging could open the door to a revolution in autonomous freight.

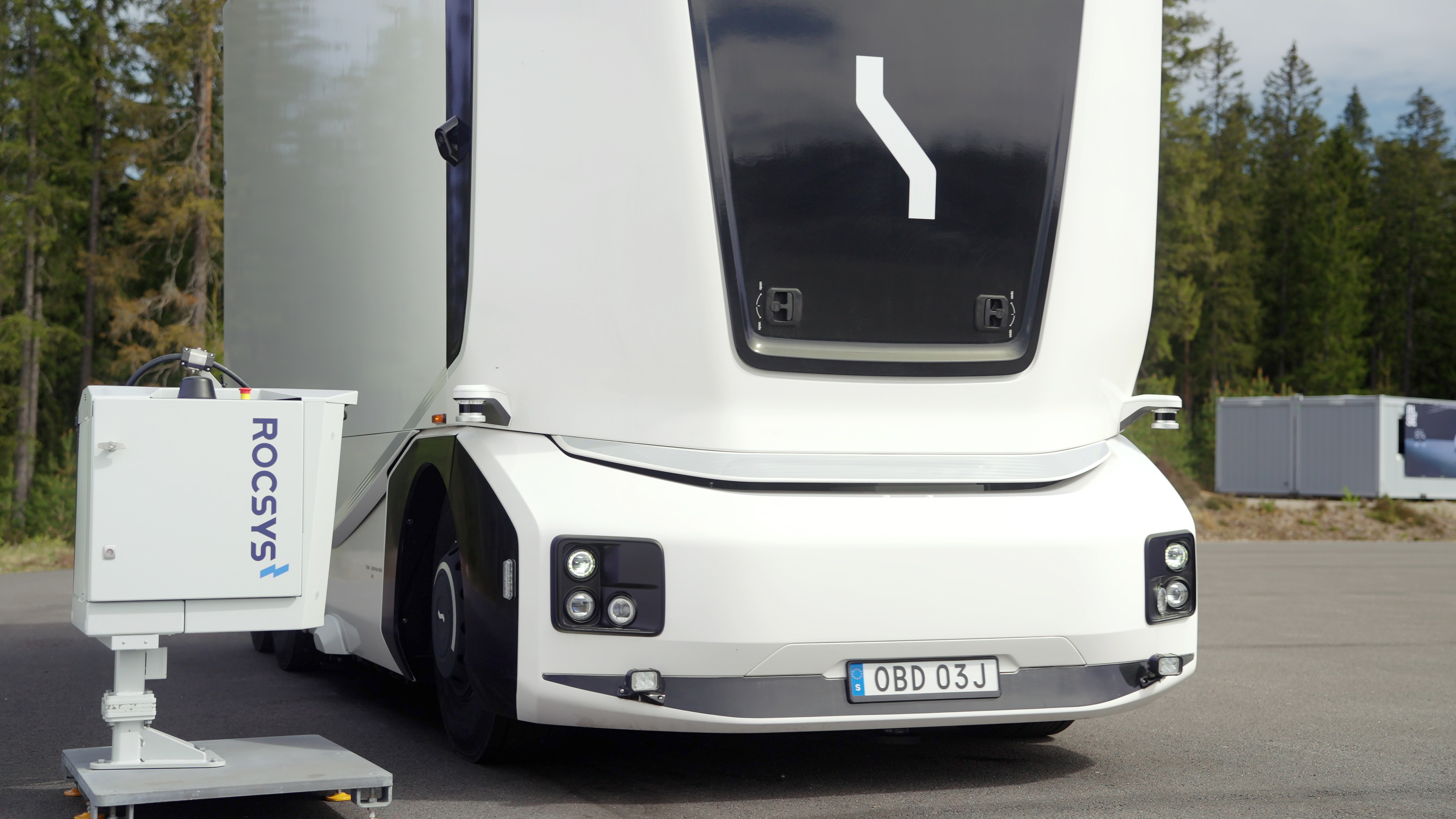

Driverless truck meets robot EV charger in Sweden as Einride and Rocsys work together. Credit: Einride and Rocsys

Thanks to our new global tariff war, the wild world of importing and exporting has been thrust into the forefront. There’s a lot of logistics involved in keeping your local Walmart stocked and your Amazon Prime deliveries happening, and you might be surprised at how much of that world has already been automated.

While cars from autonomy providers like Waymo are still extremely rare in most stretches of the open road, the process of loading and unloading cargo has become almost entirely automated at some major ports around the world. Likewise, there’s an increasing shift to electrify the various vehicles involved along the way, eliminating a significant source of global emissions.

But there’s been one sticking point in this automated, electrified logistical dream: plugging in. The humble act of charging still happens via human hands, but that’s changing. At a testing facility in Sweden, a company called Rocsys has demonstrated an automated charger that works with self-driving electric trucks from Einride in a hands-free and emissions-free partnership that could save time, money, and even lives.

People-free ports

Shipping ports are pretty intimidating places. Towering cranes stand 500 feet above the ground, swinging 30-ton cargo crates into the air and endlessly moving them from giant ships to holding pens and then turning around and sending off the next set of shipments.

This is Einride’s autonomous cargo truck. Credit: Einride

That cargo is then loaded onto container handlers that operate exclusively within the confines of the port, bringing the crates closer to the roads or rail lines that will take them further. They’re stacked again until the arrival of their next ride, semi-trucks for cargo about to hit the highway or empty rail cars for anything train-bound.

Believe it or not, that entire process happens autonomously at some of the most advanced ports in the world. “The APM terminal in Rotterdam port is, I would say, in the top three of the most advanced terminals in the world. It’s completely automated. There are hardly any people,” Crijn Bouman, the CEO and co-founder of Rocsys, said.

Eliminating the human factor at facilities like ports reduces cost and increases safety at a workplace that is, according to the CDC, five times more dangerous than average. But the one link in the chain that hasn’t been automated is recharging.

Those cargo haulers may be able to drive themselves to the charger, but they still can’t plug themselves in. They need a little help, and that’s where Rocsys comes in.

The person-free plug

The genesis of Rocsys came in 2017, when cofounder Bouman visited a fledgling robotaxi operator in the Bay Area.

“The vehicles were driving themselves, but after a couple of test laps, they would park themselves in the corner, and a person would walk over and plug them in,” Bouman said.

Bouman wouldn’t tell me which autonomy provider was operating the place, but he was surprised to see that the company was focused only on the wildly complex task of shuttling people from place to place on open roads. Meanwhile, the seemingly simple act of plugging and unplugging was handled exclusively by human operators.

No humans required. Credit: Einride and Rocsys

Fast-forward eight years, and The Netherlands-based Rocsys now has more than 50 automated chargers deployed globally, with a goal to install thousands more. While the company is targeting robotaxi operators for its automated charging solution, initial interest is primarily in port and fleet operators as those businesses become increasingly electrified.

Bouman calls Rocsys’s roboticized charger a “robotic steward,” a charming moniker for an arm that sticks a plug in a hole. But it’s all more complicated than that, of course.

The steward relies on an AI- and vision-based system to move an arm holding the charger plug. That arm offers six degrees of freedom and, thanks to the wonders of machine learning, largely trains itself to interface with new cars and new chargers.

It can reach high and low enough and at enough angles to cover everything from consumer cars to commercial trucks. It even works with plugs of all shapes and sizes.

The biggest complication? Manual charging flaps on some consumer cars. This has necessitated a little digital extension to the steward’s robotic arm. “We’ll have sort of a finger assembly to open the charge port cover, connect the plug, and also the system can close it. So no change to the vehicle,” Bouman said.

Manually opening charge port covers complicates things a bit. Credit: Einride and Rocsys

That said, Bouman hopes manufacturers will ditch manual charge port covers and switch to powered, automatic ones in future vehicles.

Automating the autonomous trucks

Plenty of companies around the globe are promising to electrify trucking, from medium-duty players like Harbinger to the world’s largest piece of rolling vaporware, the Tesla Semi. Few are actually operating the things, though.

Stockholm-based Einride is one of those companies. Its electric trucks are making deliveries every day, taking things a step further by removing the driver from the equation.

The wild-looking, cab-less autonomous electric transport (AET) vehicles, which would not look out of place thundering down the highway in any science-fiction movie, are self-driving in most situations. But they do have a human backup in the form of operators at what Einride’s general manager of autonomous technology, Henrik Green, calls control towers.

Here, operators can oversee multiple trucks, ensuring safe operation and handling any unexpected happenings on the road. In this way, a single person can operate multiple trucks from afar, only connecting when it requires manual intervention.

“The more vehicles we can use with the same workforce of people, the higher the efficiency,” he said.

Green said Einride has multiple remote control towers overseeing the company’s pilot deployments. Here in the US, Einride has been running a route at GE Appliance’s Selmer, Tennessee facility, where autonomous forklifts load cargo onto the autonomous trucks for hands-off hauling of your next refrigerator.

The trucks are overseen remotely. Credit: Einride

Right now, the AETs must be manually plugged in by an on-site operator. It’s a minor task, but Green said that automating this process could be game-changing.

“There are, surprisingly, a lot of trucks today that are standing still or running empty,” Green said. Part of this comes down to poor logistical planning, but a lot is due to the human factor. “With automated electric trucks, we can make the transportation system more sustainable, more efficient, more resilient, and absolutely more safe.”

Getting humans out of the loop could result in Einride’s machines operating 24/7, only pausing to top off their batteries.

Self-charging, self-driving trucks could also help open the door to longer-distance deliveries without having to saddle them with giant batteries. Even with regular charging stops, these trucks could operate at a higher utilization than human-driven machines, which can only run for as long as their operators are legally or physically able to.

That could result in significant cost savings for businesses, and, since everything is electric, the environmental potential is strong, too.

“Around seven percent of the world’s global CO2 footprint today comes from land transportation, which is what we are addressing with electric heavy-duty transportation,” Green said.

Integrations and future potential

This first joining of a Rocsys robotic steward and an Einride AET took place at the AstaZero proving ground in Sandhult, Sweden, an automation test facility that has been a safe playground for driverless vehicles of all shapes and sizes for over a decade.

This physical connection between Rocsys and Einride is a small step, with one automated charger connected to one automated truck, compared to the nearly three million diesel-powered semis droning around our highways in the United States alone. But you have to start somewhere, and while bringing this technology to more open roads is the goal, closed logistics centers and ports are a great first step.

“The use case is simpler,” Bouman said. “There are no cats and dogs jumping, or children, or people on bicycles.”

And how complicated was it to connect Einride’s systems to those of the Rocsys robotic steward? Green said the software integration with the Rocsys system was straightforward but that “some adaptations” were required to make Einride’s machine compatible. “We had to make a ‘duct tape solution’ for this particular demo,” Green said.

Applying duct tape, at least, seems like a safe job for humans for some time to come.