Why iRobot’s founder won’t go within 10 feet of today’s walking robots

In his post, Brooks recounts being “way too close” to an Agility Robotics Digit humanoid when it fell several years ago. He has not dared approach a walking one since. Even in promotional videos from humanoid companies, Brooks notes, humans are never shown close to moving humanoid robots unless separated by furniture, and even then, the robots only shuffle minimally.

This safety problem extends beyond accidental falls. For humanoids to fulfill their promised role in health care and factory settings, they need certification to operate in zones shared with humans. Current walking mechanisms make such certification virtually impossible under existing safety standards in most parts of the world.

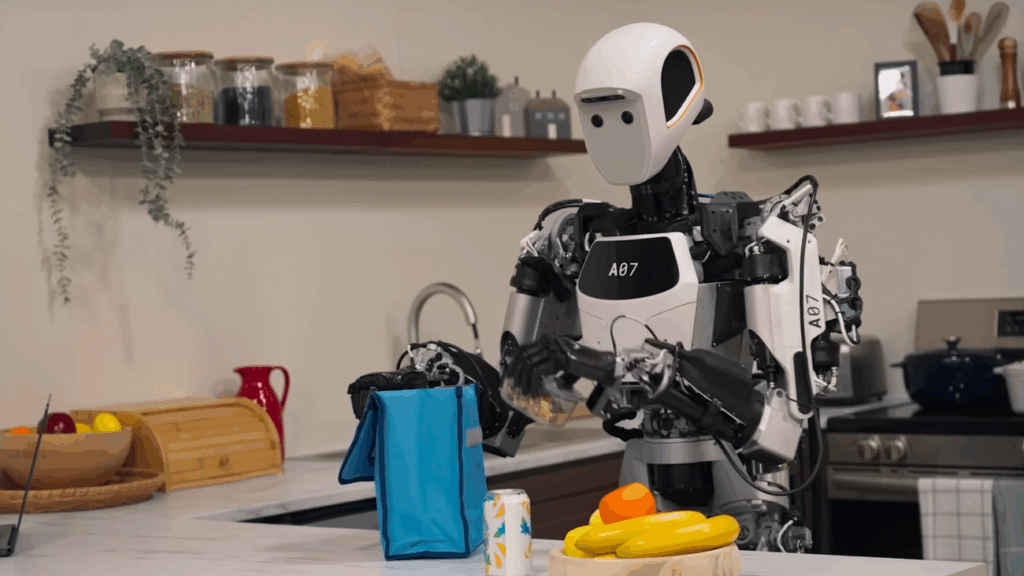

The humanoid Apollo robot. Credit: Google

Brooks predicts that within 15 years, there will indeed be many robots called “humanoids” performing various tasks. But ironically, they will look nothing like today’s bipedal machines. They will have wheels instead of feet, varying numbers of arms, and specialized sensors that bear no resemblance to human eyes. Some will have cameras in their hands or looking down from their midsections. The definition of “humanoid” will shift, just as “flying cars” now means electric helicopters rather than road-capable aircraft, and “self-driving cars” means vehicles with remote human monitors rather than truly autonomous systems.

The billions currently being invested in forcing today’s rigid, vision-only humanoids to learn dexterity will largely disappear, Brooks argues. Academic researchers are making more progress with systems that incorporate touch feedback, like MIT’s approach using a glove that transmits sensations between human operators and robot hands. But even these advances remain far from the comprehensive touch sensing that enables human dexterity.

Today, few people spend their days near humanoid robots, but Brooks’ 3-meter rule stands as a practical warning of challenges ahead from someone who has spent decades building these machines. The gap between promotional videos and deployable reality remains large, measured not just in years but in fundamental unsolved problems of physics, sensing, and safety.

Why iRobot’s founder won’t go within 10 feet of today’s walking robots Read More »