Why doesn’t Cards Against Humanity print its game in the US? It’s complicated.

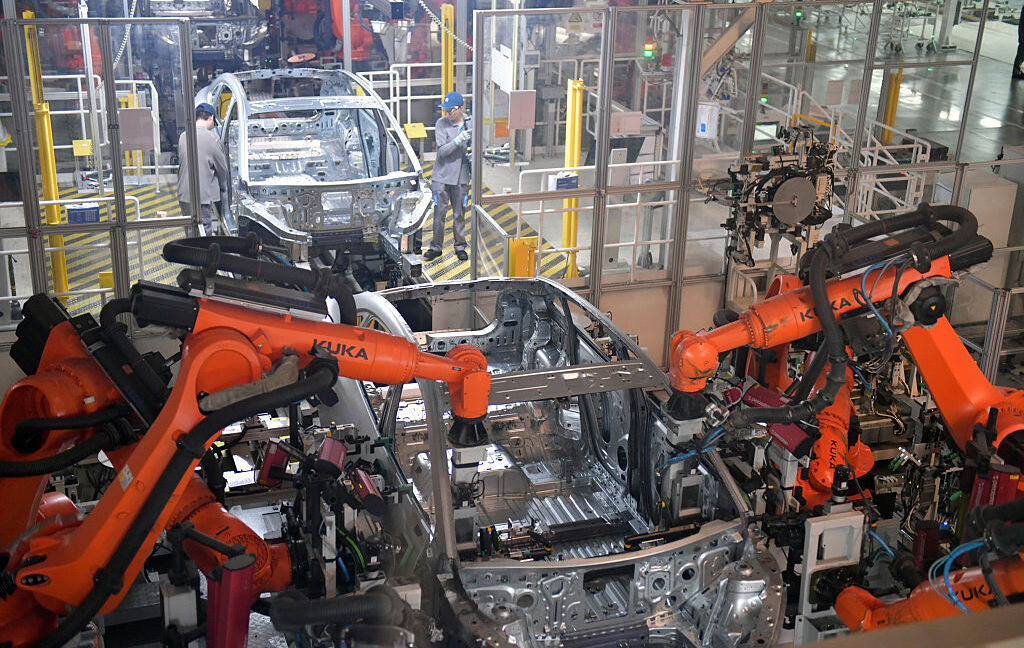

Or take Meredith Placko, the CEO of Steve Jackson Games, which produces games like Munchkin. “Some people ask, ‘Why not manufacture in the US?’ I wish we could,” she wrote. “But the infrastructure to support full-scale board game production—specialty dice making, die-cutting, custom plastic and wood components—doesn’t meaningfully exist here yet. I’ve gotten quotes. I’ve talked to factories. Even when the willingness is there, the equipment, labor, and timelines simply aren’t.”

But surely, you say, a box of cards should be possible. And it is. But CAH tells me that the downsides of US manufacturing for its game are still significant.

“We actually tried diversifying our suppliers by working with a US factory several years ago, but they were twice as expensive, three times slower, and much lower quality—something like 20 percent of games were unsellable due to production errors,” said a spokesperson for the company.

And although it is possible to print card games in the US, CAH makes other products too and would prefer to work with a single manufacturer who can handle all of it. Newer CAH games like Head Trip use “wooden tokens and a round folding board,” while another title called Tales “has a bound book and 20 tiny matchboxes of prompts.”

In the end, though, it’s not just about dollars and sense. It’s also about relationships and trust. CAH has “used the same factory in China since 2010, and they’ve grown alongside us from a small business to a huge operation,” I was told. “They do great work, we like them, and we feel a moral obligation to stand by them through Trump’s insanity.”

(If you want to produce Cards Against Humanity in the US, however, you can always download the free files for the game [PDF] and print it yourself. Be warned that it is quite vulgar!)

Board and card games are not one of the major pillars of the US economy, of course, but looking into how complicated it can be to get a game made does illuminate complex issues around globalization and manufacturing that are too often turned into simple soundbites.

Why doesn’t Cards Against Humanity print its game in the US? It’s complicated. Read More »